Laminate Flooring

|

Laminate flooring used to look like a cheap, plastic imitation of real hardwood flooring. Times have changed though with the technological advances of laminate flooring in the past decade, laminate flooring is now looking better (and more realistic) than ever. Now, you can have a beautiful, durable and affordable new floor in just a snap! Laminate flooring made its debut in the late 1970’s. At the time, tongue and grooves had to be glued together during a floating installation and the surface looked more like plastic than anything. Since then, radical changes have been made in the manufacturing process and laminate flooring went from being a cheap throw away option for homeowners to a long lasting, beautiful investment for your home. Now, glueless click lock technologies are standard on laminate flooring and digitally enhanced images make it hard for even flooring professionals to tell the difference between laminate and real wood. |

How is a Laminate Floor Made?

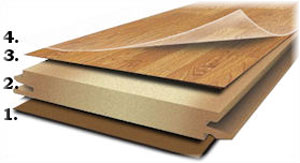

Laminate floor has 4 basic components:

|

|

The laminate floor is created when the 4 layers are pressed together using an incredible amount of pressure (from 300 to over 1300 pounds per square inch, PSI) and heat (up to 400 degrees). The sheets are then cut into individual planks and have the click lock tongue and groove edges cut into them. Afterwards, the planks go through rigorous quality inspections before being packaged and stocked. |

Direct Pressure Laminate vs High Pressure Laminate

There are 2 different types of laminate flooring that result from the pressure construction during the manufacturing process: High Pressure Laminate Flooring and Direct Pressure Laminate Flooring. Most manufacturers use a Direct Pressure Laminate (DPL) to create their laminate flooring:Armstrong and mannington are a couple examples. Direct Pressure Laminates are generally manufactured with 300 to 500 PSI. Direct Pressure Laminates have more flexible melamine impregnated decorative sheets, allowing manufacturers more flexibility when it comes to creating realistic looking patterns for the laminate floors. High Pressure Laminate (HPL) floors are made using more than 1300 PSI which results in a thicker decorative layer. High Pressure Laminate construction offers superior impact resistance, superior heat resistance and better sound reduction. Extra layers of kraft paper are added in between layers of High Pressure Laminate floors for extra stability and sound deadening properties. High Pressure Laminate floors are recommended in heavier commercial use because of their maximum durability and stronger construction. Many homeowners also love the peace of mind that comes with an exceptionally wear resistant laminate floor. |

|

|

Our work is fully guaranteed and we offer a warranty on all labor.

We are fully insured professionals who attend to the most minute detail.